Your most ambitious challenges require more than a standard catalog of products and services. We center our business around your challenges and use a forward-thinking approach to bring you the solutions of tomorrow, today.

We create integral and customizable technology platforms that support you from prototype to design to final product, getting your ideas to market faster.

We collaborate intensively with you, working through your engineering challenges and finding the right solutions for your project. Our global team of material experts and technologists are available to you throughout.

You can benefit from design support based on decades of experience, helping to optimize your designs and de-risk the innovation process.

KyronMAX™ is an award-winning range of breakthrough high strength thermoplastic composite compounds, specifically designed for rapid, complex high-spec injection molding.

Easily processed, KyronMAX™ can be molded using the same equipment and tooling as standard for unfilled resins, while compounds can be customized to meet application requirements. KyronMAX™ injection moldable materials retain high strength in complex part geometries, making them stronger, lighter and longer lasting (tougher) than other thermoplastic composite and metal parts.

Rapid prototyping offers you the possibility to quickly test and improve your designs, parts, and processes.

By allowing for rapid injection molding of functional parts with the right materials, our SPRINT (Soluble Printed Injection Tooling) technology allows us to develop, test and improve functional prototypes in just a few days. And our network of machine shops can generate full strength parts in complex geometries to help customers quickly test and proof their designs.

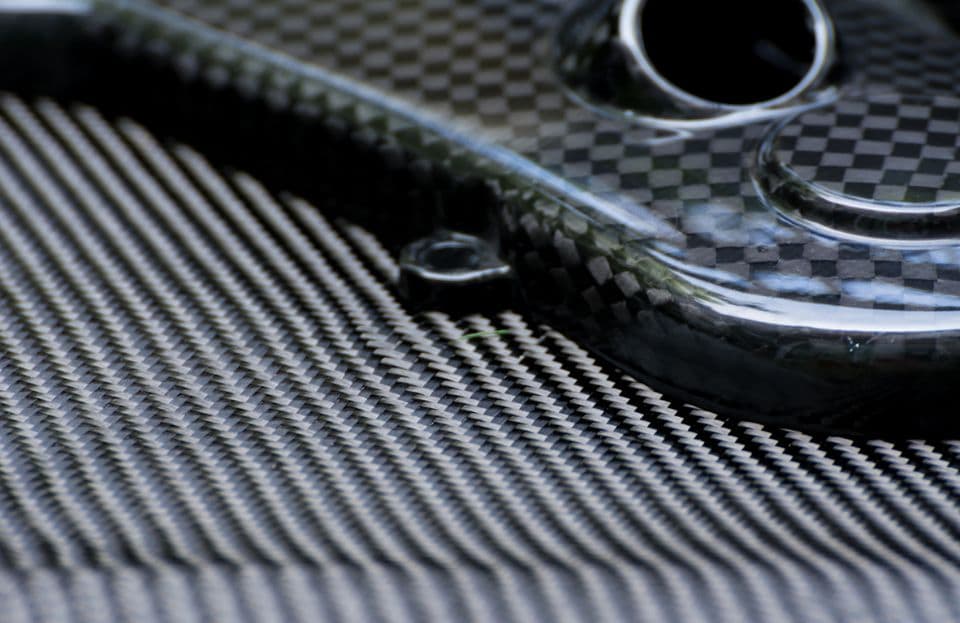

Does your application include complex, multi-layer forms with differing strengths and flexibilities? KyronTEX™ may be the material you need.

KyronTEX™ is an innovative textile-based carbon composites technology platform. It allows for high-speed scalable applications, offering drapability for more complex and predictable strength shapes, as well as the ability to sandwich various densities and compression rates layers.

Reliable part replacement in just a few weeks

Seeing beyond typical material applications, led to an innovative solution.

Working quickly, under huge time pressure, we used our broad portfolio of high-performance thermoplastic materials and rapid prototyping capabilities to help a manufacturer of equipment for the beverage bottling industry find a replacement part solution that improved overall throughput.

Delivering savings and reliability through carbon fiber expertise

Our predictive mapping technologies and rigorous testing processes informed the final re-design of commercial vehicle brackets with carbon fiber composites in place of steel. Our KyronMAX™ materials’ unique mechanical properties and new mold filling design created a more sustainable, reliable, lightweight alternative.

Improving food safety through part detectability

Working closely with both the food manufacturer and the OEM, we used our engineered solutions expertise to help re-design the food safe scraper blades used in their new diary processing tanks. We not only developed highly detectable, food safe materials that mitigated costly contamination risks, and also helped improve the equipment design processes, increasing customer satisfaction and efficiency.

A focus on quality

More sustainable solutions

Our safety pledge

Looking for something specific? Get in touch with our specialist teams by filling in the contact form. We’re ready to meet your next challenge.

Contact us