PA6 and PA66 nylons

Polyamides (PA) are a group of semi-crystalline polymers best known as nylons. Because of their balanced property profiles, nylons are among the most important and widely used engineering polymers in industry.

PA materials exhibit excellent friction behavior on top of great mechanical strength and stiffness, making them ideal for bearing and wear components. Furthermore, with as little as 1/6 the weight of steel and 1/3 the weight of aluminum, nylons are very light. This well-rounded performance profile makes polyamides an excellent option for replacing metal or rubber parts.

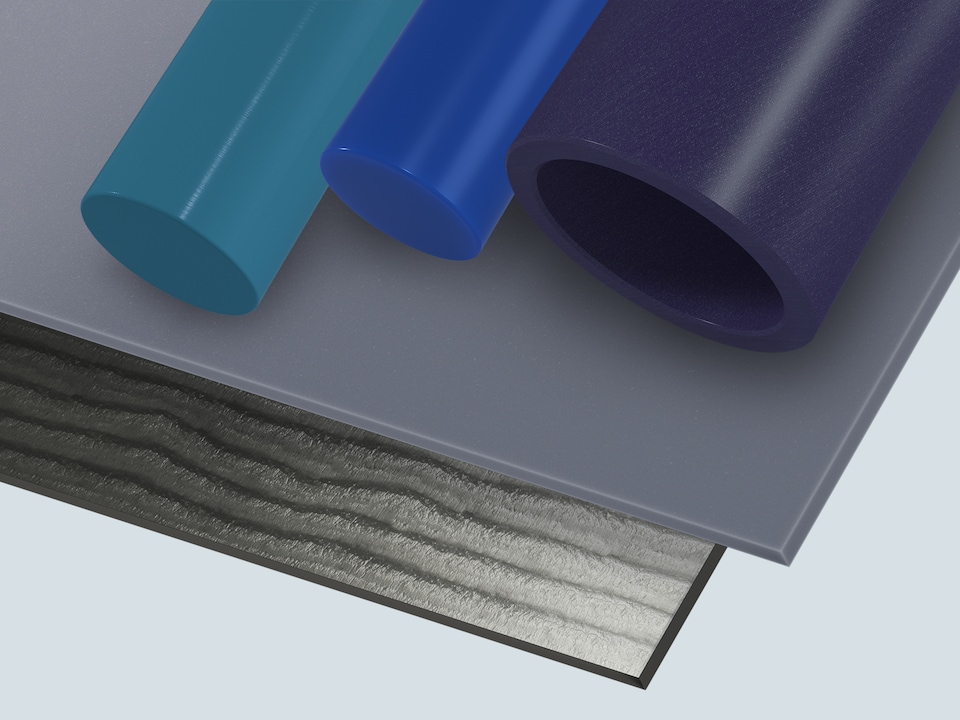

The Ertalon™ and Nylatron™ portfolio of PA6 and PA66 sheets, rods, and tubes from Mitsubishi Chemical Group encompasses a comprehensive range of standard and specialty nylon formulations for a variety of bearing and wear applications.

-

What is the difference between PA6 and PA66?

Polyamide 6 (PA6) and polyamide 66 (PA66) are two of the most important types of nylon in engineering. On a molecular level, PA66 has a slightly more complex polymer chain than PA6. While PA6 consists of a polymer chain with six carbon atoms between each group of amides, PA66 has two additional carbon atoms between amide groups.

These molecular differences result in PA66 having a higher molecular weight and higher degree of crystallinity vs. PA6. This translates to PA66 having a property profile that is superior to PA6 in terms of mechanical strength, temperature resistance, chemical resistance, and moisture absorption.

The decision between PA6 vs. PA66 will ultimately come down to budget and performance requirements. PA66 exhibits superior mechanical strength, heat resistance, and chemical resistance, but is more expensive than PA6. PA6 exhibits good performance characteristics at a lower cost than PA66, making it a preferred material for applications where the enhanced properties of PA66 are not essential.

-

Nylons in general exhibit higher thermal resistance compared to other economically priced engineering plastics such as polyethylenes, polypropylenes, acetals, and PET. PA66 materials typically display more advanced thermal properties than PA6 materials.

Unless otherwise noted, the thermal properties of nylon stated below are based tests performed on standard, unfilled grades of Nylatron™ MC 901 PA6 and Nylatron™ 101 PA66 / Ertalon™ 66 SA PA66.

Nylon heat deflection temperature (HDT)

- PA6 - 80°C (176°F)

- PA66 - 85°C (185°F)

Nylon melting point

- PA6 - 215°C (419°F)

- PA66 - 260°C (500°F)

Nylon thermal conductivity

Thermal conductivity is a measure of a plastic's capacity to transfer heat via conduction. Nylons generally exhibit lower thermal conductivity than simlarly priced thermoplastics such as PET, POM, and PC.

At 23°C (73°F), PA6 and PA66 materials from MCG exhibit the following thermal conductivity values:

- PA6 - 0.29 W/(K.m)

- PA66 - 0.28 W/(K.m)

Nylon coefficient of linear thermal expansion (CLTE)

The coefficient of linear thermal expansion (CLTE) is used to determine the rate at which a material expands as a function of temperature. As seen in the following graph, PA66 exhibits a lower CLTE than POM materials but a higher CLTE than PET. Because it is classified as a general engineering plastic, nylon also exhibits a higher CLTE than more advanced polymers like PPS and PEEK.

-

Engineering nylons are so widely used because of their well-rounded mechanical properties, including high tensile strength, good impact resistance, and impressive durability. In terms of mechanical properties, nylon's weakest point is its moisture absorption rate.

Unless otherwise noted, the mechanical properties of nylon stated below are based tests performed on standard, unfilled grades of Nylatron™ MC 901 PA6 and Nylatron™ 101 PA66 / Ertalon™ 66 SA PA66.

Nylon density

- PA6 - 1.150g/cm³

- PA66 - 1.140g/cm³

Nylon tensile strength

PA6 has the following values for tensile strength, strain, and elasticity according to ISO 527-1/-2:

- Tensile strength: 84 MPa

- Tensile strain at yield: 5%

- Tensile strain at break: 35%

- Tensile modulous of elasticity: 3,300 MPa

PA66 has the following values for tensile strength, strain, and elasticity according to ISO 527-1/-2 and ASTM D638:

- Tensile strength: 90 MPa or 12,000 PSI

- Tensile strain at yield: 5% or 4%

- Tensile strain at break: 50%

- Tensile modulous of elasticity: 3,550 MPa or 425 KSI

Nylon hardness and impact strength

PA6 has the following values for hardness and impact strength:

- Rockwell M hardness (ISO 2039-2) - 85

- Shore hardness D (ISO 868) - 80

- Charpy impact strength (unnotched, ISO 179-1/1eU) - no break

- Charpy impact strength (notched, ISO 179-1/1eA) - 3.0 kJ/m²

PA66 has the following values for hardness and impact strength:

- Rockwell M hardness (ISO 2039-2) - 88

- Shore hardness D (ISO 868) - 80

- Charpy impact strength (unnotched, ISO 179-1/1eU) - no break

- Charpy impact strength (notched, ISO 179-1/1eA) - 4.5 kJ/m²

Nylon flexural modulus and strength

PA6 has the following values for flexural strength according to ISO 178:

- Flexural strength - 131 MPa

- Flexural modulus of elasticity - 3580 KSI

PA66 has the following values for flexural strength according to ISO 178:

- Flexural strength - 135 MPa

- Flexural modulus of elasticity - 3,240 KSI

Nylon compressive strength

PA6 has the following compressive stress values according to ISO 604:

- 1% nominal strain: 32

- 2% nominal strain: 61

- 5% nominal strain: 90

PA66 has the following compressive stress values according to ISO 604:

- 1% nominal strain: 32

- 2% nominal strain: 62

- 5% nominal strain: 100

Nylon moisture absorption

Nylons are more hygroscopic that most engineering plastics, meaning they absorb moisture from the surrounding environment. This moisture absorption can lead to dimensional changes, reduced mechanical properties, and altered electrical properties in engineering applications, making it crucial to consider and control moisture exposure when using nylons in humid or wet conditions.

After 24 hours of immersion in 23°C (73°F) water, PA6 and PA66 has the following water absorption values:

- PA6 - 0.72%

- PA66 - 0.6%

At saturation in 23°C (73°F) water, PA6 and PA66 has the following water absorption values:

- PA6 - 6.6%

- PA66 - 8%

Nylon wear rate

According to ISO 7148-2, PA6 and PA66 exhibit the following wear rates:

- PA6 - 12 µm/km

- PA66 - 14 µm/km

-

Nylons exhibit good resistance to a wide range of chemicals, especially oils, fuels, gasoline, mineral spirits, hydrocarbons, and some alcohols. Their resistance to oils, fuels, and gasolines (combined with their light weight) has made nylon an indispensible material in automotive and aerospace applications.

Due to their relatively higher moisture absorption rates, nylons may have limited chemical compatibility in applications where exposure to moisture-sensitive chemicals or prolonged exposure to humid environments is a concern, such as in hot washing applications. Nylons are not compatible with acids.

- Aerospace, automotive, and mobility - For their lightweight, resistance to oils and fuels, and great wear performance, PA6 and PA66 components are indispensible materials for engine mounts, gears, bearings, and bushings in the automotive and aerospace industries.

- Renewable energy - Self-lubricating nylon grades are increasingly replacing bronze materials in wind energy applications such as gearbox oilrings and yaw slide bearings.

- Food, beverage, pharma, and packaging - Food grade nylons are often utilized for wear components in the food, beverage, and pharma industries in applications like bushings, bearings, gears, and wheels.

- Heavy machinery - With great impact resistance and wear behavior, nylons are especially prevalent in wear pad applications in heavy machinery. Specialty grade nylons with precision stick-slip properties are favored for machinery such as cranes, extendable booms, and cherry pickers.

Nylatron™ & Ertalon™ Product Family

Browse the full range of the Nylatron™ and Ertalon™ Product Family, including both PA6 and PA66 formulations developed for a comprehensive range of heavy duty engineering applications.

Engineering plastic wear pads

For applications in heavy machinery and other industries, our advanced polymers provide superior wear resistance, reduced friction, and high mechanical strength for heavy-duty wear pads.

MatFind

Quickly find the optimal engineering plastic for your application. Simply input the performance properties you require, and MatFind will help you filter and compare materials.

Looking for something specific? Get in touch with our specialist teams by filling in the contact form. We’re ready to meet your next challenge.

Contact us