Glass fiber reinforced composite materials

Glass-fiber reinforced thermoplastics are a versatile class of materials that offer engineers a distinct combination of high strength, low weight, and affordability. Because of their excellent mechanical performance at a fraction of the weight, glass-reinforced polymers are commonly used to replace metals in structural and semi-structrual applications. The Mitsubishi Chemical Group provides a comprehensive portfolio of high-performance glass-fiber reinforced polymers including GMTex™, GMT, SymaLITE™, and MultiQ™ materials.

Carbon fiber reinforced composite materials

Rewrite what’s possible in engineering with the broadest portfolio of carbon composite materials. By replacing traditional materials with scalable, cost-effective carbon fiber composites, engineers can achieve previously impossible performance requirements and sustainability goals. The Mitsubishi Chemical Group provides a comprehensive portfolio of high-performance carbon-fiber reinforced polymers including KyronMAX™, Forged Molding Compound™, recycled carbon fibers, and more.

Prepreg and textile composites

Mitsubishi Chemical Group is your leading global partner in the composites sector, with cutting edge production technologies for the manufacture of prepregs and textile composites on three continents. Our custom prepreg solutions find application in diverse industries including aerospace, automotive, boat building, medical technology, industry and heavy machinery, and renewable energy. The comprehensive portfolio of prepregs includes cutting edge technologies such as KyronTEX™ and BIOpreg PFA.

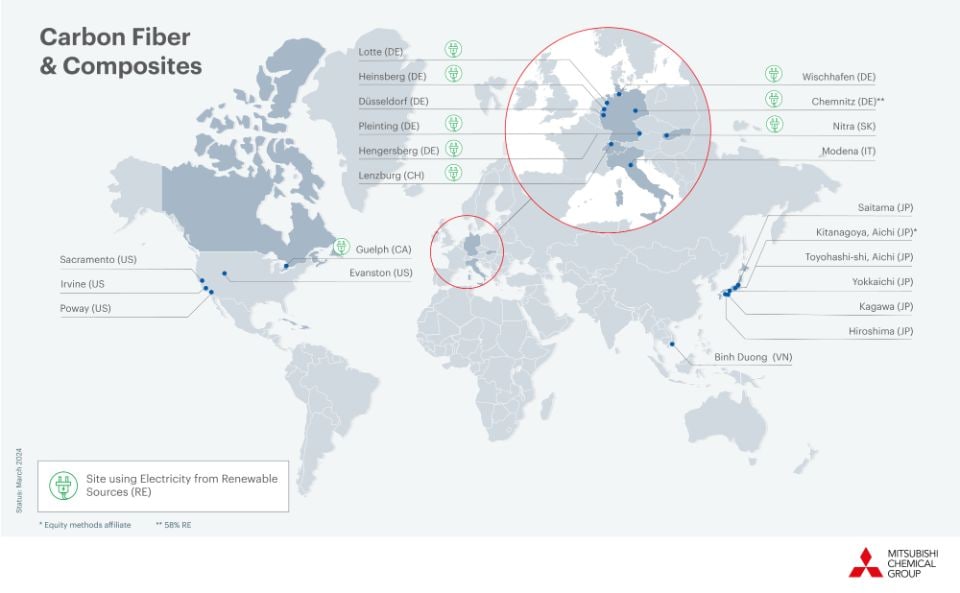

Powered by renewable energy

Explore which of MCG's Carbon Fiber & Composites global facilities are powered by renewable energy.

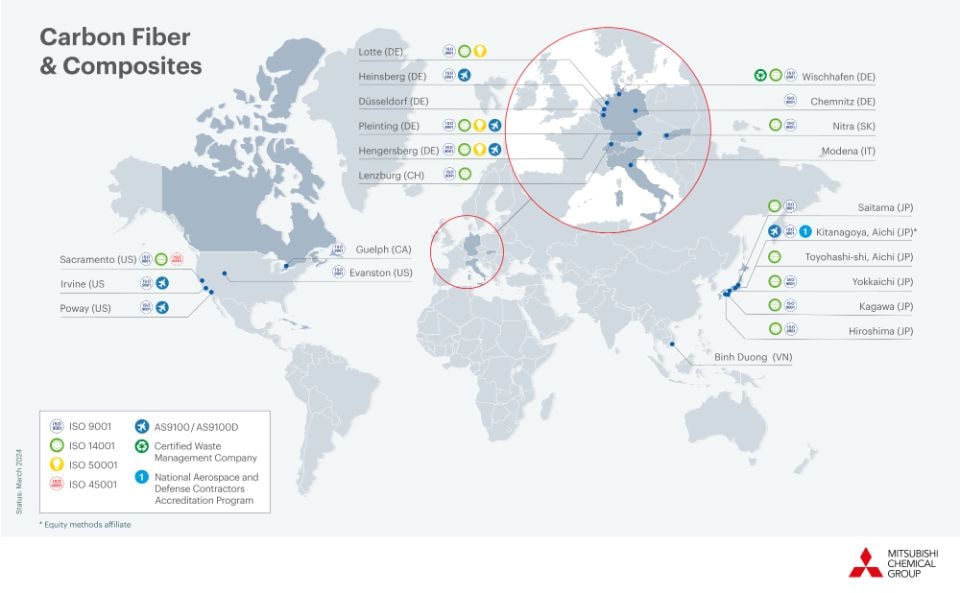

Certifiably sustainable

Explore which of MCG's Carbon Fiber & Composites global facilities are certified to international sustainability standards.

From raw materials to scrap collection and recycling, our Composites Toolbox can help bring market-driving, scalable innovations to life across a range of industries and previously unfeasible applications. We partner with OEMs and engineers to give them the tools they need to successfully replace traditional materials with cost-effective, future-ready composite materials.

By constantly broadening our portfolio and simplifying the implementation process, our Composites Toolbox is always evolving to provide high-performance, highly functional, and cost-efficient solutions. With our collaborative approach and extensive portfolio, we’ll help you find precisely the right composite materials and tools to transform your products and processes.

From understanding the raw materials to improving product recycling and waste reduction, we partner with our customers to help them navigate the complexities of designing with composites in a practical, user-friendly way. Our collaborative approach and extensive know-how regarding materials and industries allow us to constantly innovate our existing portfolio, adding more sustainable materials and processes at a specifiable, scalable, and consistent quality.

We’re constantly researching, developing, and investing in composite materials to offer our customers the latest in lightweight, high-strength and high-performing part solutions – sourced from the widest portfolio of thermoplastic and thermoset composites, including recycled carbon fibers (rCF). Our flexible production processes and innovative technologies allow us to create bespoke polymer composite solutions that expand what’s possible.

Our large, global network and vertically integrated supply chain enable us to apply next generation manufacturing processes and scalable, cost-efficient production methods to even the most complex engineering applications.

We’re reducing landfill waste and making a sustainable future possible by supporting circular manufacturing and end-of-life waste programs. Our broad portfolio of customizable, recycled carbon fiber intermediates and semi-finished products, supported by a take-back service of carbon-fiber-reinforced polymer (CFRP) materials and parts (production scrap or end-of-life CFRP), help us manufacture CFRPs at an industrial scale with a low emission footprint, contributing to a cleaner, more sustainable future for everyone.

Rewriting the manufacturing process with KyronTEX™

From test material and prototype design to final improved product.

Our composites experts shared KyronTEX™, with our partner Oribi and together we helped realign their production processes and create a more cost-effective, better-quality motorcycle helmet.

Developing scalable and cost-effective car body panels with carbon fiber prepregs

Streamlining processes to reduce emissions and production costs

Our composites experts helped a leading automotive manufacturer apply a highly flexible prepreg to lower production costs and emissions in producing and painting body panels for their vehicles

More carbon fiber, less carbon footprint

CarboNXT recycled carbon fiber products are made from reclaimed scrap materials in a pyrolysis process, offering the strength and lightness of virgin carbon fiber with lower emissions and greater circularity.

Reducing aircraft emissions with recycled composites

New materials and processes redefine sustainable manufacturing in the aerospace sector

We are helping Boeing work towards reducing the amount of aerospace waste going to landfills with recyclable materials and composite technologies.

Looking for more information, a bespoke solution, or access to product datasheets? Get in touch with our specialist composite teams by filling in the contact form. We’re ready to meet your next challenge.

Contact us now