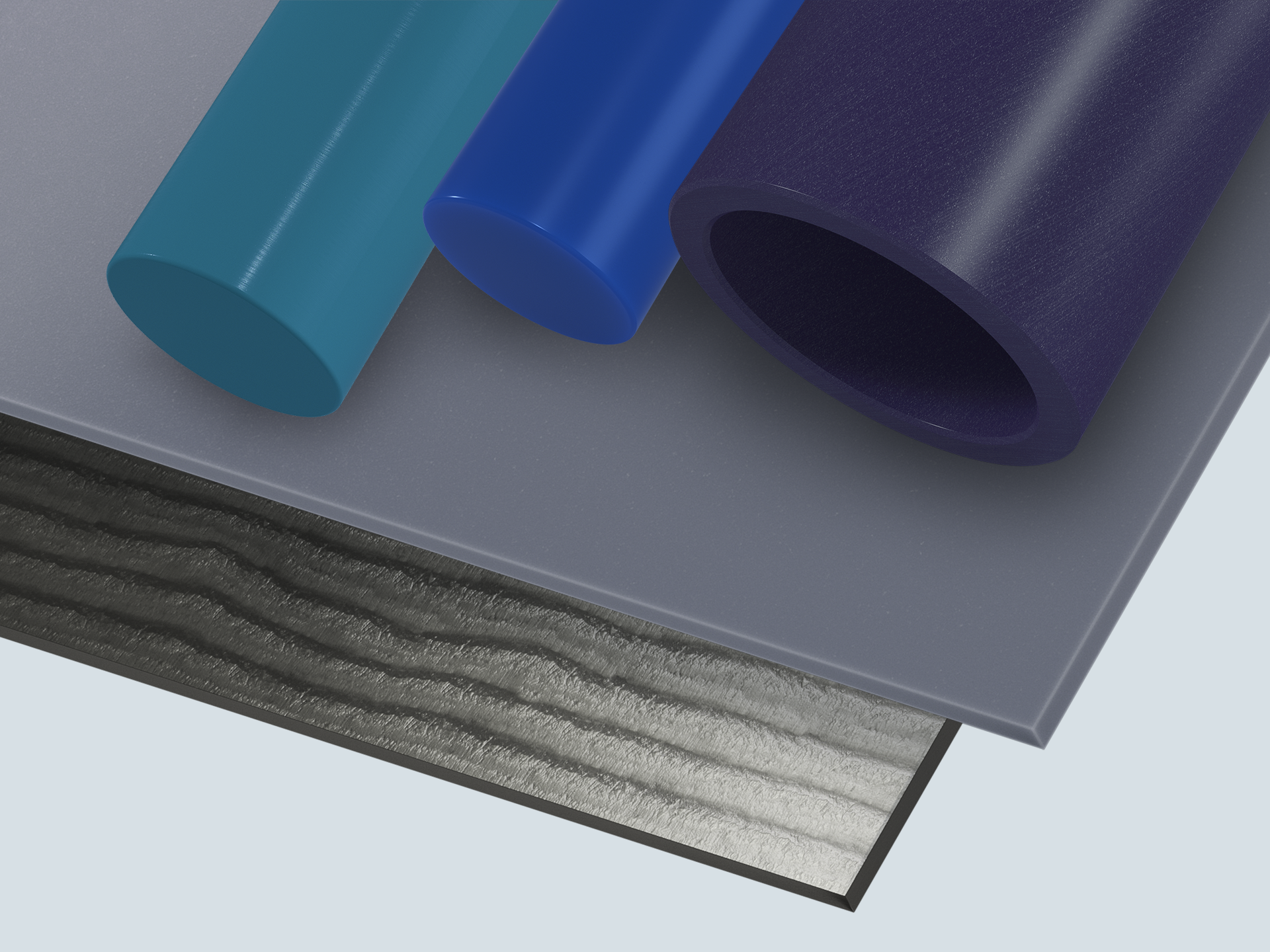

Nylatron™ / Ertalon™

Ertalon™ and Nylatron™ are a range of high-performance nylon materials with high toughness, a low coefficient of friction, and excellent wear resistance. These properties make them the industry standard for use in bearing and wear applications, and ideal replacements for materials ranging from bronze to rubber. Our comprehensive range of semi-crystaline polyamide materials includes special formulations for demanding applications requiring extremely low wear rates, near zero stick-slip, internal lubrication, long-term thermal stability, and high pressure velocity.

)

Products in the Nylatron™ / Ertalon™ family ({{ productsCount }})

Material properties at a glance