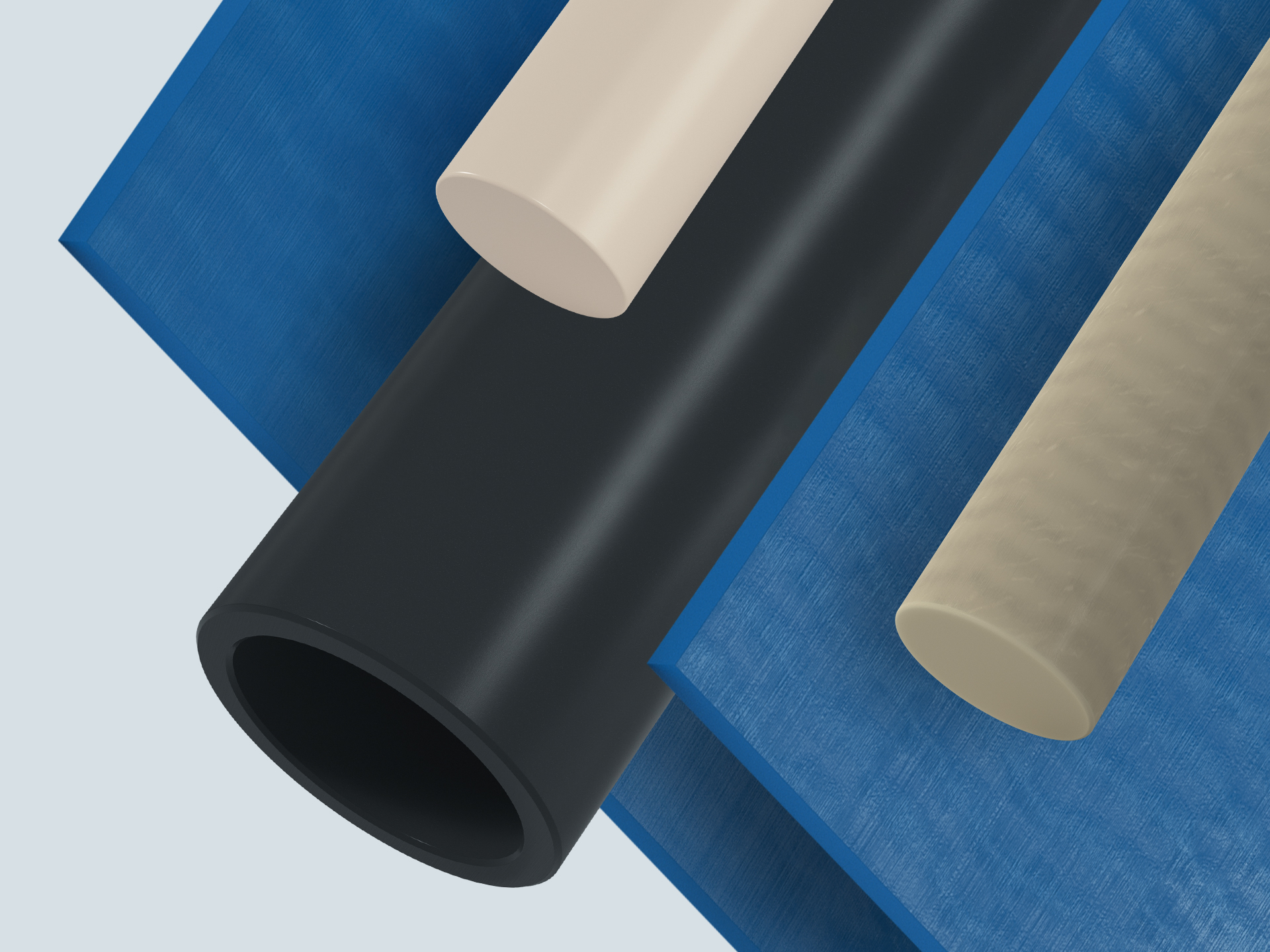

Techtron™

Techtron™ PPS (polyphenylene sulfide) products close the price and performance gaps between standard and advanced engineering thermoplastics. Our range of Techtron® materials offer the broadest resistance to chemicals of any advanced engineering plastic. They have no known solvents below 200 °C and offer inertness to steam, strong bases, fuels and acids. Minimal moisture absorption and a very low coefficient of linear thermal expansion, combined with stress relieving processes, make these PPS products ideally suited for precise tolerance machined components. In addition, PPS products exhibit excellent electrical characteristics and are inherently flame retardant. These materials are an excellent alternative to PEEK at lower temperatures.

)

Products in the Techtron™ family ({{ productsCount }})

Material properties at a glance