Choose from semi-finished plastic products for every budget and application

No matter the performance requirements of your application, you’ll find what you need from our offering of semi-finished thermoplastic products. Our engineering plastics exhibit many high-performance properties, and our experts help you find a material with the right combination of attributes, including superior mechanical strength, dimensional stability, and chemical resistance. Careful attention is given to how our products perform in different high-temperature settings.

Our range of engineering thermoplastic materials, from standard to extreme, is available in a wide selection of shapes and formats, including rods, sheets, tubes, and profiles. Many of our products can also be produced using Near Net Shapes to optimize your project cost, reduce your waste product, and improve your time-to-market. Direct Formed shapes are also available for some of our materials, giving you the most precise components possible, particularly when machining for tight tolerances and demanding operating environments.

Standard Plastics

For applications up to 65°C (149°F), you can improve component performance with our portfolio of standard polyethylene and polypropylene grades. These engineering polymers give you a range of high-performance properties, including greater impact strength, corrosion resistance, and superior malleability.

View allBrands in this portfolio

Engineering Plastics

Reduce weight and improve performance, reliability, and safety. Our portfolio of Engineering Plastics includes UHMW-PE, PET, nylon, acetal, and more, with each material displaying consistent mechanical performance over a broad temperature range (from 65°C and 120°C or 150°F to 250°F), as well as good machinability, electrical properties, and chemical resistance.

View allBrands in this portfolio

Advanced Engineering Plastics

Achieve predictable mechanical performance over a broad, elevated temperature change. Our Advanced Engineering Plastics portfolio includes high-performance grades of PEEK, PTFE, PEI, PSU, and PPS that were developed for operating environments between 120°C and 230°C (250°F to 450°F). Materials in this category provide improved dimensional stability and creep resistance, electrical characteristics, and superior chemical resistance.

View allBrands in this portfolio

Extreme & Imidized Plastics

Explore our most advanced thermoplastics, specifically developed for use in extreme operating environments with temperatures falling between 230°C and 425°C (450°F and 800°F). Covering imidized materials such as PI, PAI, and PBI, these shapes exhibit properties like superior strength and thermal resistance help you overcome challenges with wear, friction, sealing, and more.

View allBrands in this portfolio

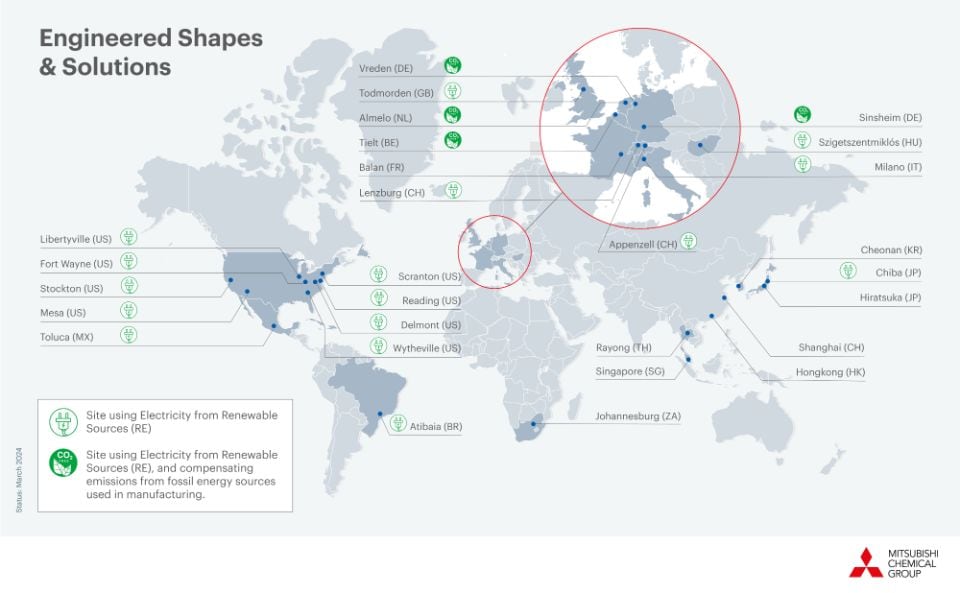

Powered by renewable energy

Explore which of MCG's Engineered Shapes & Solutions global facilities are powered by renewable energy.

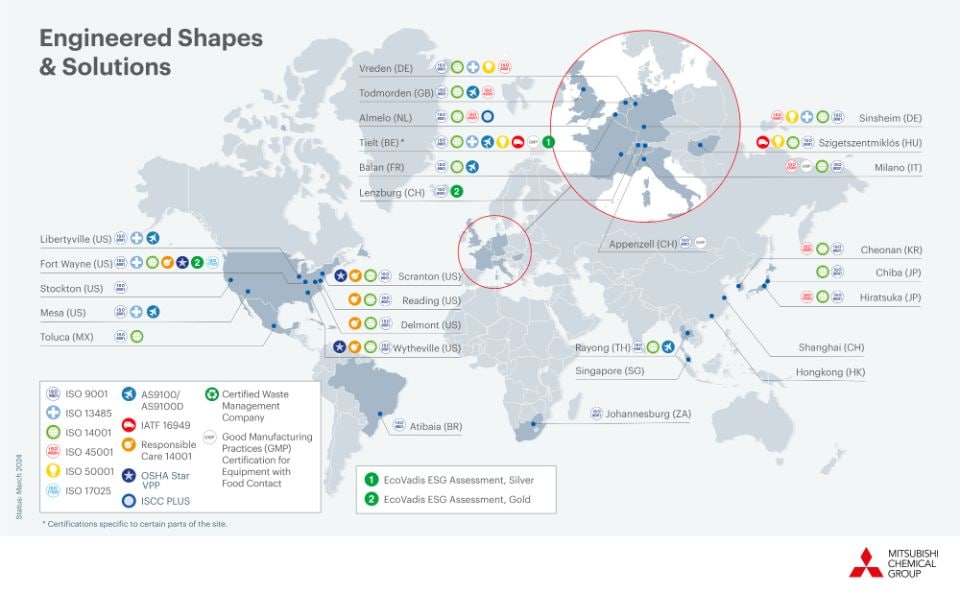

Certifiably sustainable

Explore which of MCG's Engineered Shapes & Solutions global facilities are certified to international sustainability standards.

Looking for something specific? Get in touch with our specialist teams by filling in the contact form. We’re ready to meet your next challenge.

Contact us