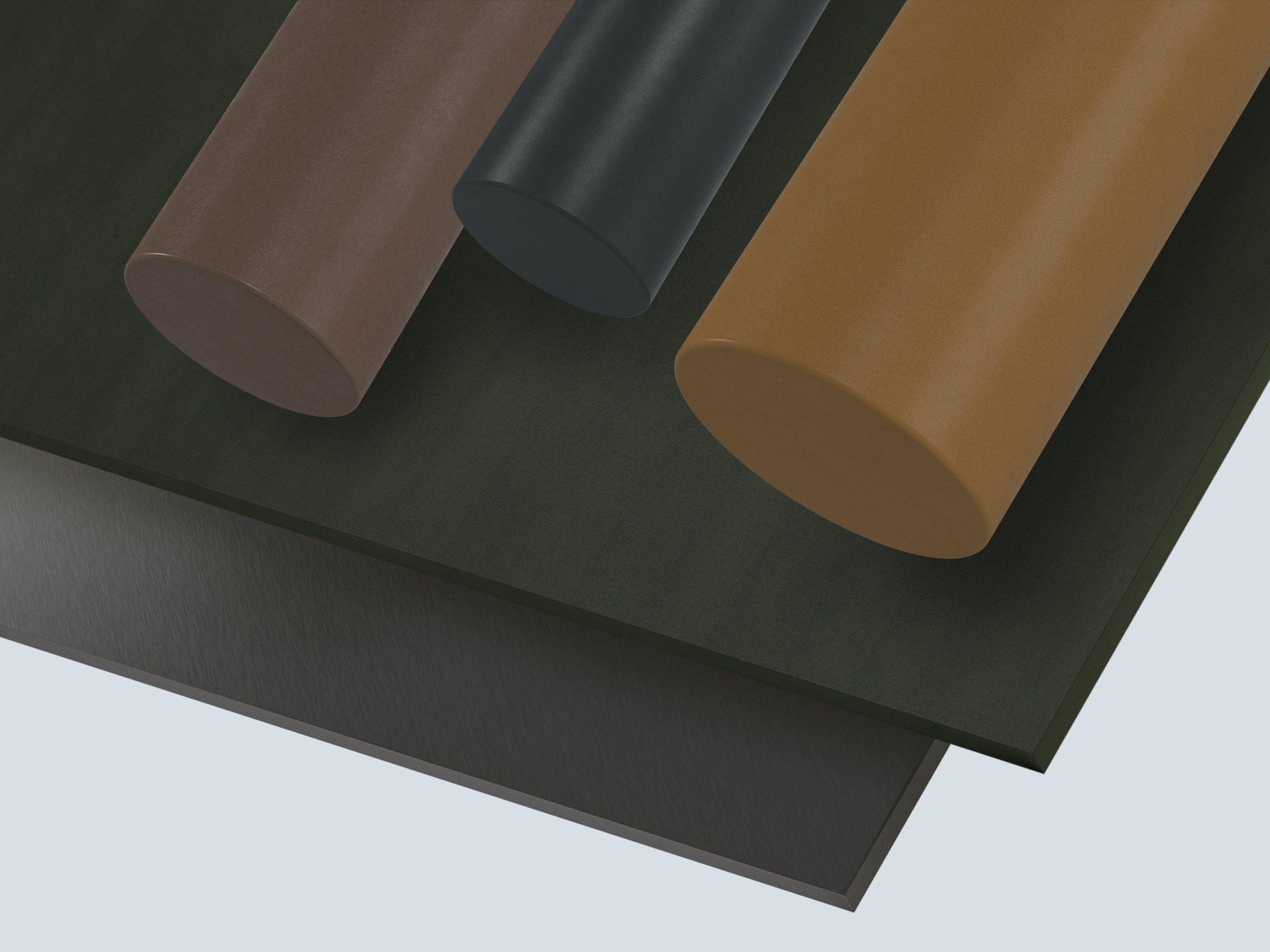

Duratron™ PI

Duratron™ PI (polyimide) stock shapes and direct formed parts are made from robust polyimide resins for demanding applications where exceptional thermal resistance, low wear and low friction, strength and impact resistance are required. Duratron™ PI offers properties that help to overcome sealing, friction, and wear challenges, that can endure high temperature and stands up to the harsh operating environments of the aerospace, transportation, and industrial applications. Duratron™ PI is an exceptional value for applications requiring high strength, stability, and load-bearing capabilities in extreme temperatures over a long service life. Duratron™ PI is available in several grades for structural and wear applications and in the broadest range of shapes - particularly thick sheets, larger sheets geometries and heavy-wall tubes.

)