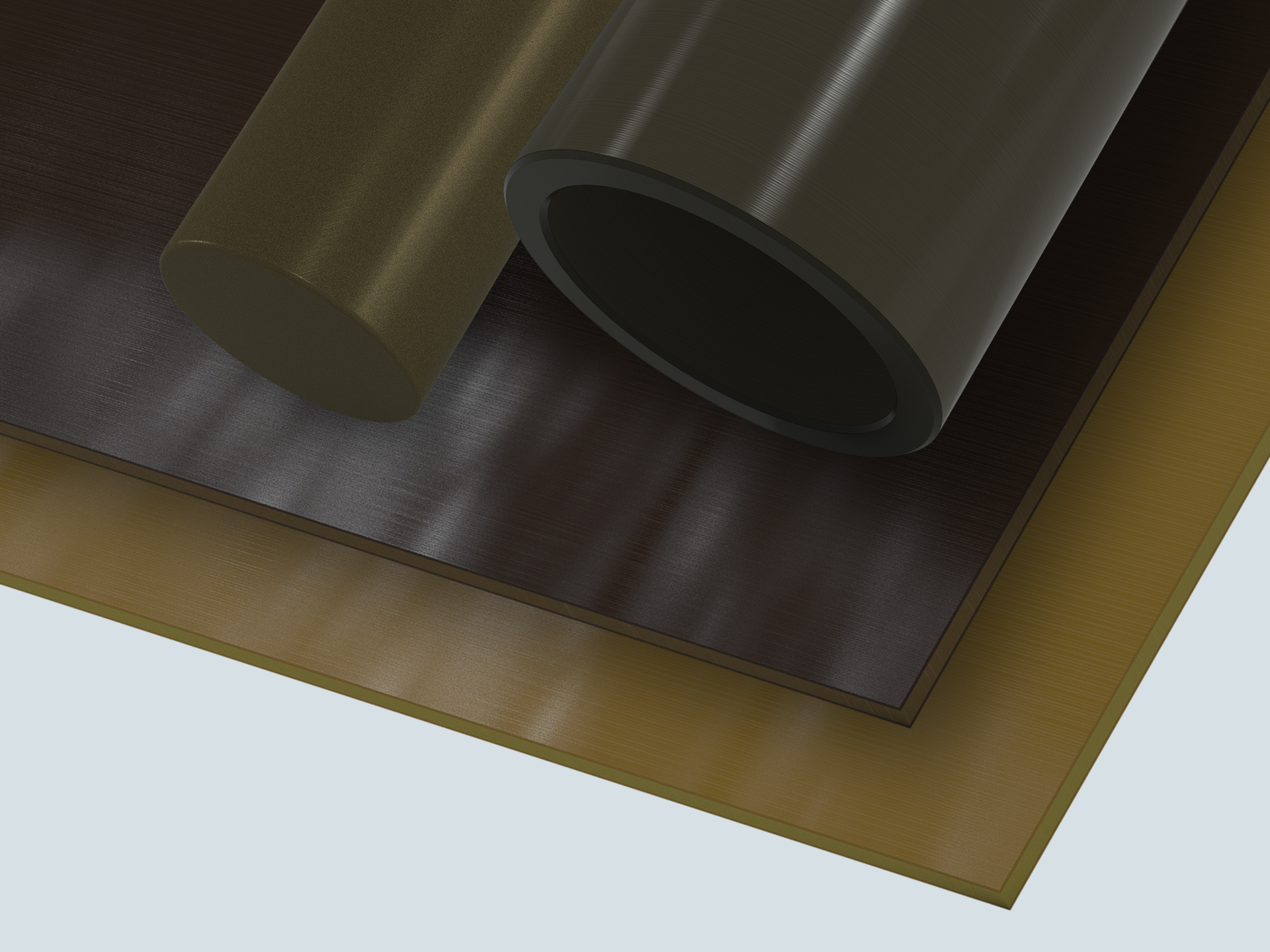

Duratron™ PAI

Duratron™ PAI is a family of the highest performing, melt processable plastics, characterized by superior resistance to elevated temperatures. These plastic grades are capable of performing under severe stress conditions at continuous temperatures to 260 °C (500 °F). Parts machined from Duratron™ PAI stock shapes provide greater compressive strength and higher impact resistance than most advanced engineering plastics. An amorphous material with a Tg (glass transition temperature) of 537°F (280°C), Duratron® PAI's extremely low coefficient of linear thermal expansion and high creep resistance deliver excellent dimensional stability over its entire service range. A post-curing cycle is sometimes recommended for components fabricated from extruded shapes where optimization of chemical resistance and/or wear performance is required. For large shapes or custom geometries like tubular bar, compression molded Duratron™ PAI shapes offer designers the greatest economy and flexibility.

Common applications of Duratron™ PAI products include electrical connectors, bearing cages, mandrels, chip nests and sockets, and labyrinth seals.

)