Sultron™

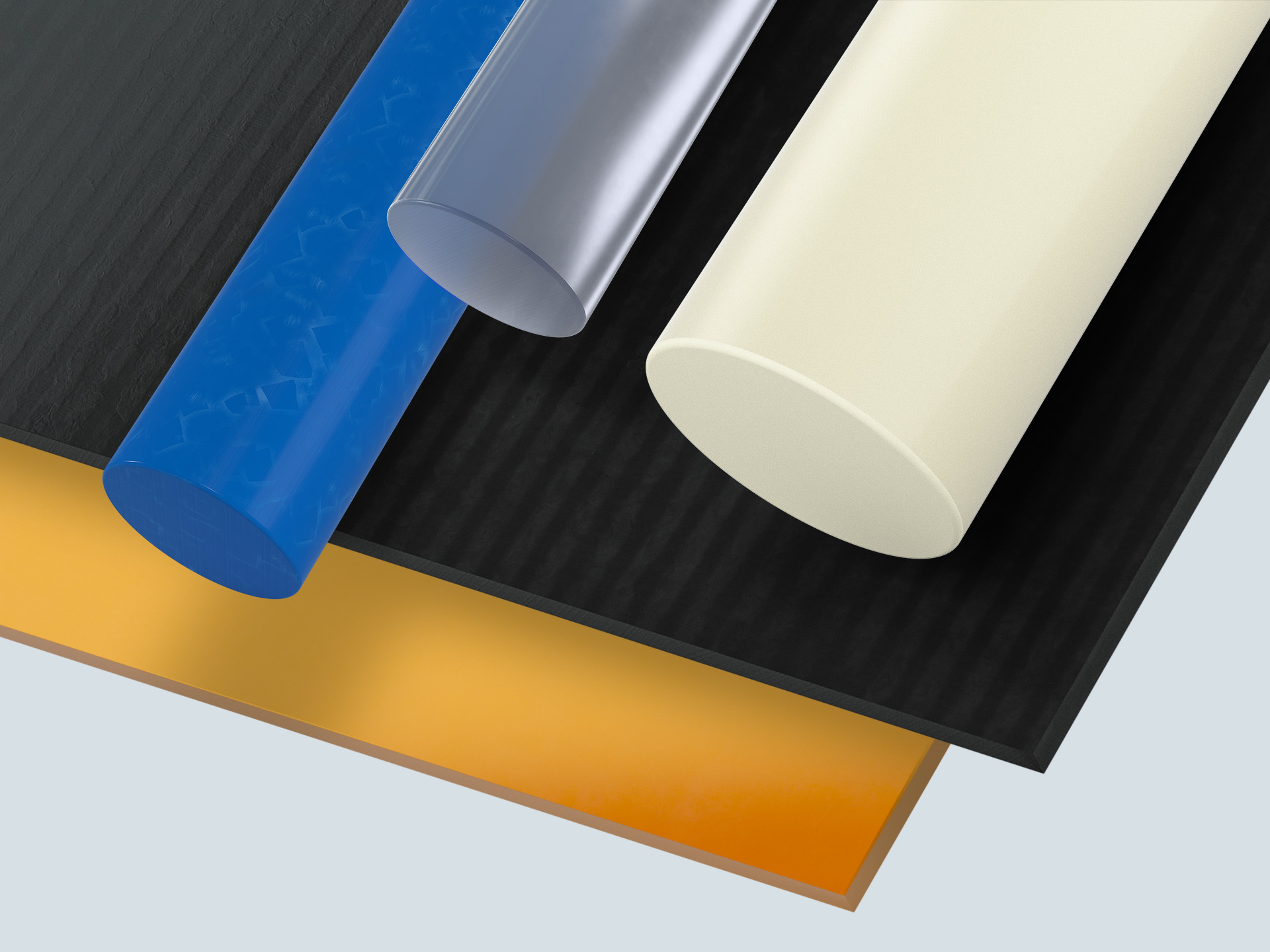

Sultron™ PSU is a family of polysulfone products that offer high chemical resistance to acidic and salt solutions, and good resistance to detergents, hot water and steam. In addition, polysulfone has excellent radiation stability, and offers low ionic impurity levels.

)

Products in the Sultron™ family ({{ productsCount }})

Material properties at a glance