Ketron™

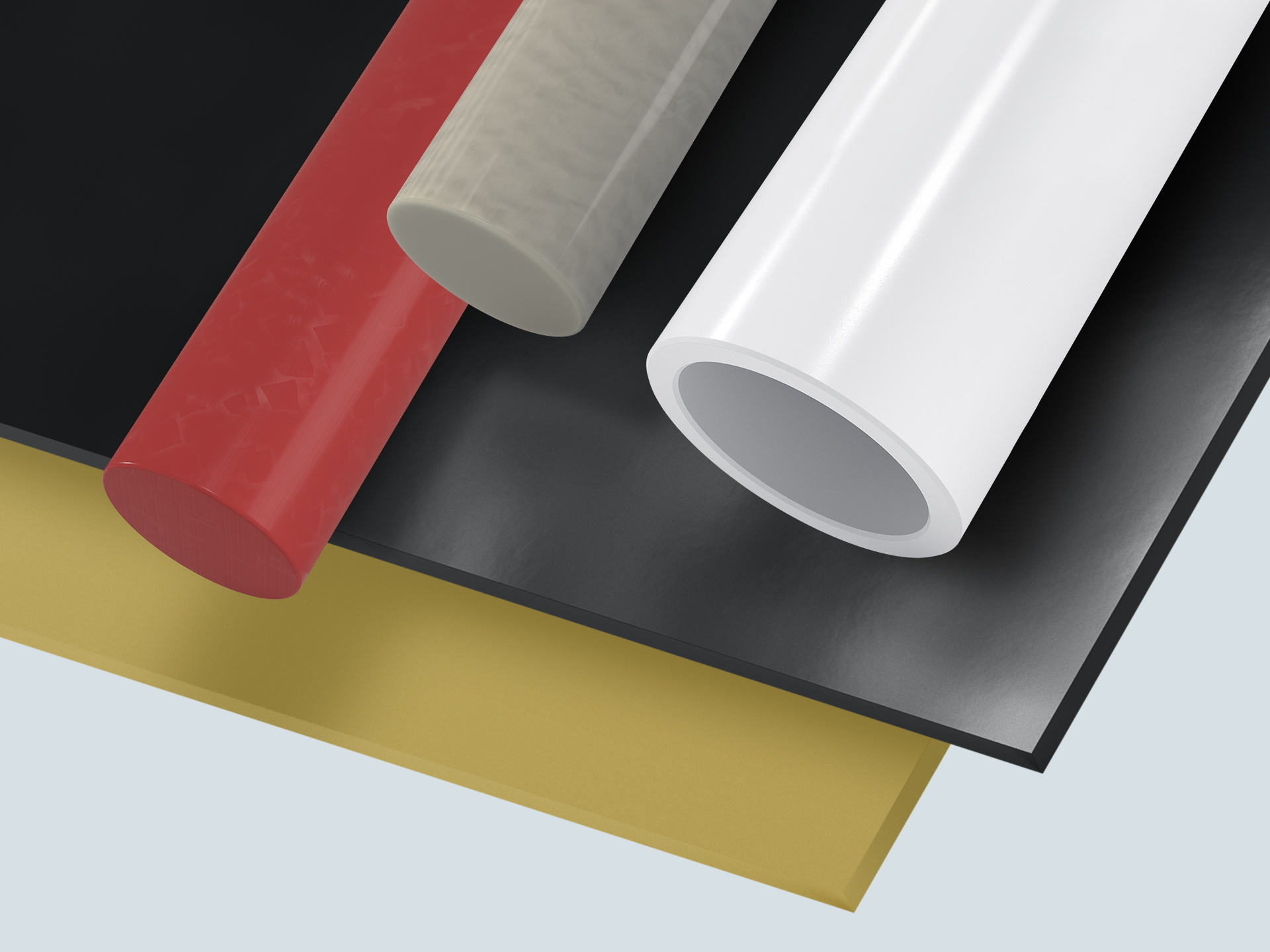

The Ketron™ PEEK family of materials is based on polyetheretherketone resin. This semi-crystalline advanced engineering material exhibits a unique combination of high mechanical properties, temperature resistance and excellent chemical resistance – making it the most popular advanced plastics material. Our comprehensive portfolio of Ketron™ products offers formulations that build on the excellent performance attributes of PEEK to offer specific properties to excel in the most demanding applications. Our range of Ketron™ products includes carbon fiber and glass fiber reinforced grades for improved mechanical characteristics, as well as grades offering internal lubrication, better load-carrying capabilities, and food-contact suitability.

)

Products in the Ketron™ family ({{ productsCount }})

Material properties at a glance