革新的なサービスとテクノロジー

弊社の特定用途向けの開発体制では、お客様の様々な開発案件に対して素早く試作品を制作いたします。さらに世界規模の供給体制により、お客様がより早く製品化を実現できるようお手伝いします。

弊社の特定用途向けの開発体制では、お客様の様々な開発案件に対して素早く試作品を制作いたします。さらに世界規模の供給体制により、お客様がより早く製品化を実現できるようお手伝いします。

弊社には専門的な材料ソリューション、熱可塑性プラスチック、複合材の包括的なポートフォリオが揃っており、これと弊社のシステムおよびテクノロジーを用いて、適切な素材を素早く見つけることができます。

弊社のKAITEKIという信条の下、循環型経済に対する弊社の責任、材料のリサイクルにおける新しい可能性を両立させることで、お客様が地球規模の持続可能性に対する責任を果たせるようにしています。

全世界46か所に所在する弊社のネットワークは、先を見越したサポート、インサイト、ひらめきを提供し、航空学から生物科学まで、様々な業界のお客様がアイデアを実現できるよう支援しています。

弊社の専門家が、お客様のニーズを満たすだけでなく、故障のリスクが少なく、メンテナンスの必要性が軽減された、より軽量の航空機を製造できる、自己潤滑性プラスチックソリューションを作成しました。これはさらに、燃料効率の増大とCO₂排出量の削減につながり、より持続可能な航空機の製造に貢献しました。

耐久性が高く、製造が容易なプラスチック給油リングを開発

弊社の専門家がお客様と協力し、風力タービンで使用するギアボックスの青銅給油リングに代わる部品を開発しました。サイズの大きな部品は応力耐性を持ち、操作が容易で、手頃な価格で製造できる必要があります。弊社の代替部品はこれらの要件を満たしながら、マシニング加工にかかる時間とコストを削減しました。

一般的な素材の用途を超えた、革新的なソリューションを開発。

弊社の熱可塑性プラスチック材料の幅広いポートフォリオと迅速な試作能力を活用し、飲料ボトリング製造装置メーカーが迅速かつ適切に交換部品を選定して、全体的なスループットを向上させられるよう技術支援しました。

弊社の解析技術と厳格な試験プロセスを用いて、金属に代わってカーボンファイバー複合材を使用した事業用車両のブラケットの開発に貢献しました。弊社のKyron™MAX素材特有の機械的特性と新しい成形設計によって、持続可能性、信頼性が向上し、より軽量になった代替材料を作成できました。

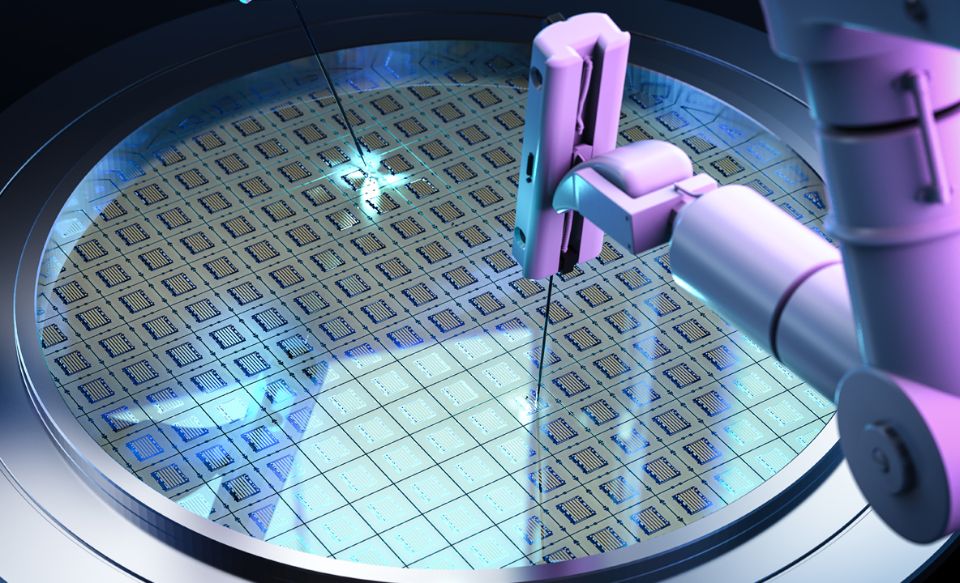

ハイテク、高性能用途に適した新しい材料の開発

半導体製造装置メーカーのお客様と連携して、実際の用途で積極的に機能のベータ試験を行いながら、仕様を満たすように開発中の素材を改良しました。弊社の強化ポリアミドイミドが、通常のポリイミド(PI)より持続期間が長い酸素クリーニング浸食耐性を実現しました。