En tant qu'entreprise chimique mondiale de premier plan, nous tirons profit de notre présence internationale et de nos équipes d'experts afin de proposer des solutions polymères complètes pour les applications du médical et des sciences de la vie.

En partenariat avec des équipementiers et des ingénieurs du secteur de la santé, Mitsubishi Chemical Group offre la puissance combinée de matériaux hautes performances, des conseils d'experts en matière de conformité, et un réseau mondial de sites de fabrication modernes équipés de salles blanches et de technologies automatisées. Nous mettons à la disposition de nos clients des capacités techniques sophistiquées, la gestion d'une chaîne logistique mondiale et une assurance qualité à la hauteur des équipements médicaux qu'ils fabriquent pour améliorer la vie de leurs patients.

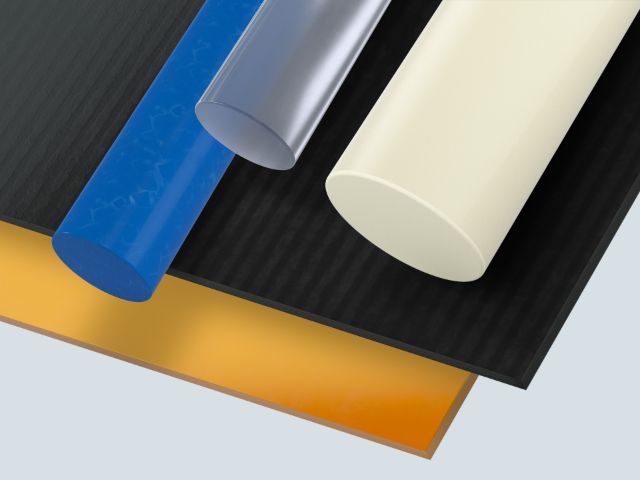

Produits Extrulen™ et Chirulen™ PE-UHMW enrichis avec des antioxydants

Les antioxydants contenus dans les produits PE-UHMW peuvent prolonger la durée de vie des implants en réduisant l'oxydation des produits standard et réticulés. Extrulen™ et Chirulen™ peuvent être enrichis en antioxydants afin de réduire le potentiel d'oxydation ou neutraliser les radicaux libres générés lors de la réticulation par irradiation. MediTECH peut fournir des produits standard à base de vitamine E et mélanger au besoin des antioxydants spécifiques, ou des concentrations d'antioxydants différentes, pour répondre aux nouveaux besoins de l'industrie.

.jpg/jcr:content/MediTECH_Chirulen_artificial_knee_joint_P6123212-20(2).jpg)

PE-UHMW Extrulen™ et Chirulen™ réticulé

Il a été démontré que la réticulation des produits PE-UHMW augmente la résistance à l'usure des implants orthopédiques. Par exemple, l'équilibre entre la résistance mécanique et l'usure est influencé par le niveau de réticulation et spécifié en fonction de la dose d'énergie fournie. MediTECH peut fournir des produits pour tous les niveaux de rayonnement afin de répondre aux besoins des clients La réticulation peut être personnalisée par rayons gamma, faisceaux d’électrons ou rayons X en fonction des besoins de l'application et des exigences du client.

Le nouveau règlement européen sur les dispositifs médicaux (RDM) apporte des changements majeurs qui auront un impact sur la façon dont les fabricants d’équipements médicaux abordent le processus de sélection des matériaux.

Dans ce webinaire, organisé en novembre 2023, trois experts vous expliquent les changements réglementaires, leurs implications pour le processus d’approvisionnement en matériaux polymères et les mesures que les fabricants d’équipements peuvent prendre pour s’y préparer.

Nos experts vous aident de la conception à la production, en passant par le développement, partout dans le monde.

Le corps humain est complexe, tout comme les réglementations et approbations nécessaires pour commercialiser de nouveaux équipements médicaux. Nous aidons nos clients du secteur de la santé à évaluer les données relatives aux matériaux (y compris nos pré-évaluations de biocompatibilité). Ceci est destiné à leur fournir une sélection solide et personnalisée de matériaux candidats pour leur application et les exigences réglementaires auxquelles ils adhèrent.

Notre offre client apporte une aide majeure à la sélection et à l'application, car les polyéthylènes implantables MediTECH sont fabriqués selon la norme ISO 13485, pré-évalués pour la biocompatibilité, et leur fourniture est 100 % traçable de la matière première, au produit semi-fini usinable. La disponibilité fiable des produits est garantie grâce à l'intégration mondiale de nos accords de distribution entre les sites de production européens et nord américains.

Contactez notre équipe de spécialistes en remplissant le formulaire de contact. Nous sommes prêts à relever votre prochain défi.