射出成形部品によって製造を簡素化

弊社の複合材料とプラスチック射出成形材料の優れたポートフォリオ、エンドツーエンドの成形設計支援、プロトタイプ作成とテストの最先端テクノロジーを紹介します。

自動車から医療、電子工学用途に至るまで、弊社グループでは、機能が重要なシステムで使用するための射出成形部品を設計、テスト、および生産しています。

射出成形部品は、最終製品の他の部分と複雑な方法で連携しています。これらの部品は、高機能性と機能上の標準を満たす必要があるだけでなく、利用者の知覚に大きく影響します。

1933年の射出成形プログラムの開始以降、弊社グループは、この分野におけるテクノロジー、知識、および機能を継続的に開発し、お客様に他に類を見ない性能とコスト削減をもたらす射出成形部品を生産してきました。

弊社の射出成形サービスの中核となるもの:

- 射出成形材料の広範なポートフォリオ

- 成形の専門知識と設計支援

- 最先端のプロトタイプ作成とテスト

射出成形可能な材料

弊社の技術サービスチームは、お客様と緊密に連携して、部品機能と予算の指定に関する内部関係者の理解を深めながら、お客様が広範なポートフォリオから最適な射出成形可能プラスチックまたは複合材を選択できるようお手伝いします。

市場にある多くのエンジニアリングプラスチックは材料成形でのみ利用可能ですが、弊社の豊富な製品群では、エンジニアリングプラスチック素材のポートフォリオの大部分で射出成形が可能です。これらには、弊社の汎用エンジニアリングプラスチック(PA、PP、POM)およびErtalyte™PET-PやTechtron™PPSの材料が含まれます。極度な機械的強度を必要とする特に要求の厳しい用途については、このオファリングは一連の高度な複合材および熱可塑性プラスチック(KyronMAX™カーボンファイバー複合材、Duratron™PAI、Duratron™PEI、Ketron™PEEKなど)にまで及びます。

部品から成形までの設計支援

射出成形プラスチック部品の生産におけるエンドツーエンドのパートナーとして、部品設計と成形設計を専門的に支援します。設計支援サービスでは、専門分野に特化した多数のテクノロジー(製造性考慮設計(DFM)、組立性考慮設計(DFA)、分解性考慮設計(DFD)など)と広範なコンピュータ支援設計ツールを活用します。

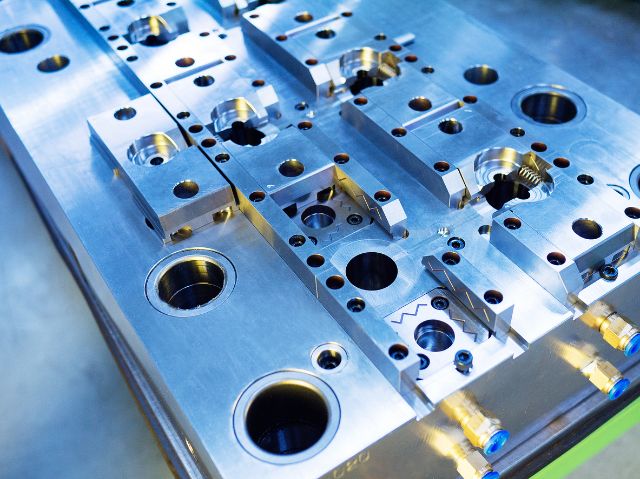

成形部品の生産性と耐用年数には、採用される工具の品質との直接的な相関関係があります。高品質な社内の成形能力によって、生産効率を高め、設計仕様から円滑に成形部品を生産できるようにします。熟練したエンジニアが最先端の金型製造機器を使用し、多数個取り金型、ホットランナー、インサート成形システム、オーバーモールディングシステムなどの広範な高品質工具を開発して、部品の寿命を改善すると同時に、製品化までの時間を短縮します。

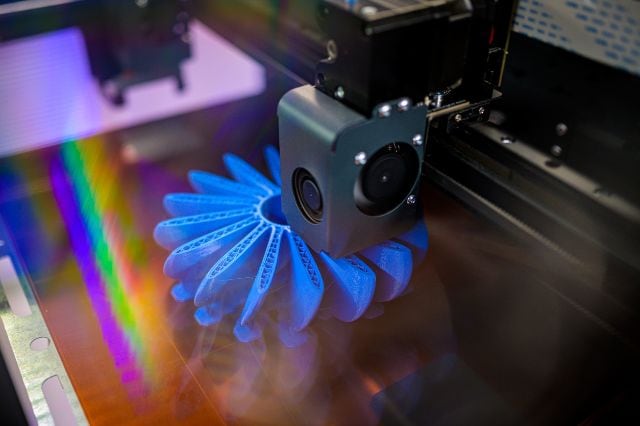

試作品作成の高速ソリューション

弊社の柔軟なSPRINT(Soluble Printed Injection Tooling)ソリューションを使用すれば、 ほんの数日で実用的な射出成形プロトタイプを開発できます。これらのSPRINTプロトタイプは高い精度と品質を示し、テストを簡素化して成形のコストとリードタイムの両方を削減します。さらに、弊社グループは、インサートの成形を置き換えることができる幅広いマスターツールをご提供する会社です。これにより、同じ成形ハウジングで異なる部品のプロタイプを作成することができ、工具コストとリードタイムが大幅に削減され、さらには、小さな連続する射出成形部品の費用対効果の高い生産が可能となります。

自動化された射出成形

お客様の費用対効果と最高品質を実現するために、弊社グループは、高レベルの自動化を射出成形工程に統合しています。この自動化は、主に組み立て、品質保証、および包装に導入されており、人的エラーをなくして一貫性を保つことで「欠陥品ゼロ」を実現します。アップストリームの自動化は樹脂材料処理や、包装や最終製品の輸送などのその他の成形後の操作にも適用されています。

クリーンルームでの射出成形

最先端の製造施設の一部として、弊社グループは、600㎡の認証済みのClass 100,000(ISO 8)のクリーンルームを運営しています。これにより、会社は、医療テクノロジーや、コンプライアンスに厳しい衛生要件が不可欠なその他の業界における現在の最高工業標準に準拠できます。

2Kおよび3K成形

弊社の製造工程は、最新の射出成形テクノロジーで構成されています。手法には、複数部品成形、二重射出、一体成形や分割成形用の出没可能なトランスファー成形が含まれ、これにより、製品組み立ての時間とコストを削減できます。ティールト(ベルギー)とブダペスト(ハンガリー)の両方にある拠点には、専用の2-Kおよび3-K(部品)成形機能があります。

様々な業界にわたる射出成形部品

医療

世界中の病院、医師、医学研究所、および研究施設を対象としたプラスチック装置や機器の生産は、厳格な品質と衛生の要件に従う必要があります。このような要件に対応するために、弊社の製品開発は、技術的な専門知識、最先端の製造施設、規制に関する詳細な知識、および高度な自動化に依存しています。弊社が製造する医療部品には、射出成形光学部品、使い捨て製品、家庭用診断製品、一般的なヘルスケア製品などがあります。クリーンルームでの射出成形も利用可能です。

自動車

三菱ケミカルグループ株式会社は、自動車業界における複数の主要な国際的サプライヤーを対象に部品を開発しながら、単一の垂直統合型ソースに沿って製品の開発、生産、および組み立てを行っています。弊社の高精度の射出成形部品は、電気系統、ボンネット内、および内装用途の安全性を保証します。

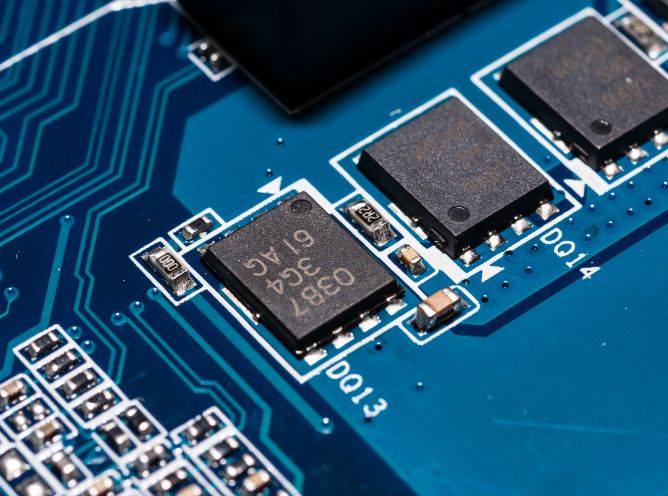

電気および電子工学

弊社は、製品と成形を同時に開発するための専門知識により、外装の美しさとともに内部の高度化を持続的に向上させることが求められる電子工学市場において、プラスチック部品とシステムの設計および製造の理想的なパートナーとなります。これらのうち注目すべき用途には、技術ハウジング、骨組み、支持体、電磁部品があります。

工業

三菱ケミカルグループ株式会社には、エンジニアリングと高機能プラスチックの広範なポートフォリオを開発しながら培った、製品設計における豊富な専門知識と長年の経験があります。工業用途において、弊社の高度な熱可塑性樹脂部品は、最高の機能標準を満たし、信頼性の高い荷重耐性能力、高温耐性、およびその他重要な特性を備えています。

機能包装

三菱ケミカルグループ株式会社は、飲料、日用品、在宅ケアに積極的に取り組む会社を対象に、大規模なエンジニアリング支援活動を行っています。弊社は共同パートナーとして、お客様の差し迫ったニーズに応えるだけでなく、製品範囲全体にわたり特定の目的に向けた革新的なソリューションを開発するお手伝いをすることで、長期的な価値を生み出します。

弊社グループは、射出成形サービスを2つの主要な拠点で運営しており、どちらの拠点にも、最高の品質と一貫性を追求した完全自動化の組み立て機能が備わっています。弊社の最先端機器には、30から800メートルトンのクランプ力を持つ射出成形機などがあり、2部品や3部品の射出成形機も複数含まれます。これらの施設では、生産のために成形を継続的に利用できるよう、施設内の工具の迅速な修理、サービス提供、および改良も行っています。

ティールト、ベルギー(16,600 ㎡ - 約168,000 ft2)

この生産施設では、CAD、成形、工具の修理とメンテナンス、プロタイプ作成、射出成形、テスト、2次操作(組み立て、印刷、塗装、殺菌消毒)、ロジスティクス、配送、および社内における工具開発を専門に扱っています。

シゲトセントミクローシュ(ブダペスト)(6,600 ㎡ - 約71,000 ft2)

この生産施設でのサービスは、射出成形、工具の修理とメンテナンス、テスト、2次操作、調整、ロジスティクス、および配送を網羅しています。

射出成形部品の製造は製造業者とサプライヤーの緊密な連携を必要とします。弊社グループは、垂直統合型で全工程をサポートするパートナーとして、設計支援や材料選定に関する助言を含め、初期段階から開発工程と生産工程を連携させられるように支援します。弊社の射出成形サービスは、自動車、医療、電気および電子工学用途など、さまざまな業界に先端部品を提供します。