Dans nos installations de Lenzburg, en Suisse, nous transformons vos déchets thermoplastiques postindustriels en granulés recyclés de haute qualité.

En nous appuyant sur des décennies d'expertise et sur les dernières technologies de recyclage pour le tri, le traitement et le contrôle de la qualité, nous garantissons la grande qualité de nos recyclats et contribuons à la disponibilité continue de granulés recyclés viables.

Alternative commercialement attrayante aux plastiques vierges, ces matériaux bruts retraités sont utilisés de diverses manières, notamment dans la création de produits plastiques techniques semi-finis et de formes à contenu recyclé.

- Processus de recyclage certifiés ISO 9001

- Priorité au recyclage des plastiques techniques hautes performances

- Numéro un mondial du retraitement du PEEK, des plastiques fluorés et des polyamides

- Composition personnalisée et fabrication à façon avec des matériaux bruts recyclés

- « Mettre en oeuvre KAITEKI », le bien-être durable des personnes, de la société et de notre planète

.jpg/jcr:content/Mingafluor-PVDF-natur-1000x550px%20(1).jpg)

Mingafluor

Nos systèmes de recyclage sont conçus pour préserver les performances des plastiques fluorés. Notre gamme est constituée de granulés fabriqués à partir de :

- PVDF (polyfluorure de vinylidène)

- ECTFE (éthylène chlorotrifluoroéthylène)

- PFA (perfluoroalkoxylalcane)

- Composés

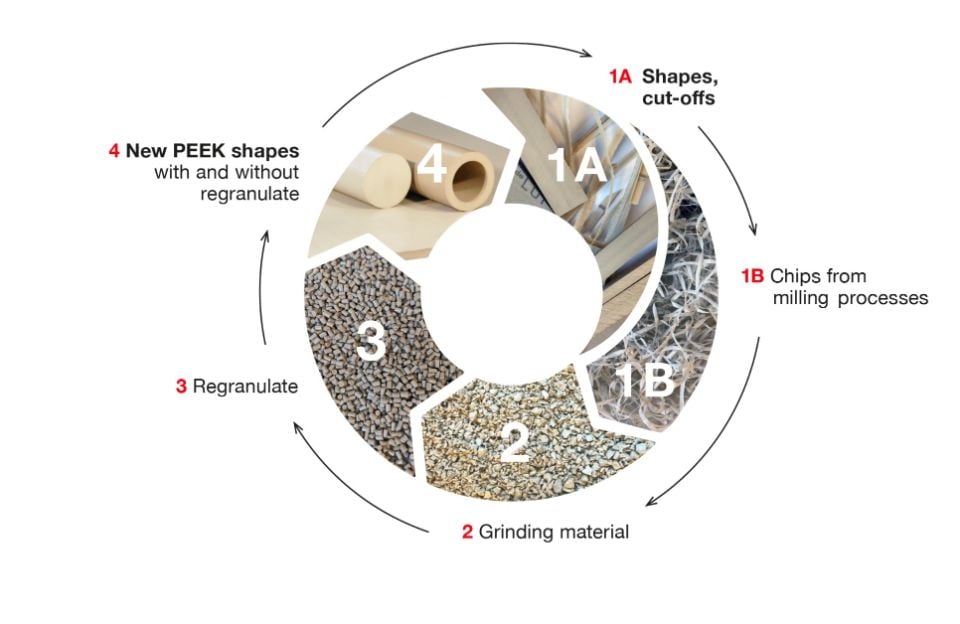

MingaPEEK

Notre méthode de recyclage propriétaire lave efficacement les copeaux et les pièces moulées pour produire des granulés de PEEK recyclé répondant aux normes les plus élevées.

- PEEK (polyétheréthercétone)

- Micro PEEK

- Composés de PEEK

Mingamid

Granulés de nylon recyclé de qualité constante, produits à partir de déchets industriels propres et triés, traités en flux unique.

- Polyamide 6

- Polyamide 11

- Polyamide 12

Mingalen et Mingaprop

Granulés de polypropylène et de polyéthylène recyclé pour la fabrication de pièces moulées par injection et extrudées.

- PE (polyéthylène)

- PP-C (copolymère de polypropylène)

- PP-H (polypropylène homopolymère)

Vous cherchez quelque chose en particulier ? Contactez notre équipe de spécialistes en remplissant le formulaire de contact. Nous sommes prêts à relever votre prochain défi.

Contactez-nous