Les pièces et garnitures d’étanchéité jouent un rôle essentiel dans le fonctionnement des machines et des mécanismes techniques en prévenant les fuites et les fermetures non sécurisées. La résistance des joints de vannes, joints labyrinthe, inserts de sièges et autres pièces d’étanchéité dépend du matériau dans lesquels ils sont faits, et des conditions dans lesquelles ils sont utilisés.

Nos polymères hautes performances offrent des solutions d'étanchéité de grande tenue dans de multiples applications et secteurs industriels. Notre gamme comprend des matériaux conçus pour offrir des niveaux de fonction supérieurs sous de multiples conditions. La résistance mécanique, la stabilité dimensionnelle et la résistance à l’usure de nos solutions garantissent un fonctionnement optimal dans les environnements les plus extrêmes.

Le défi : l’un des joints du sas à sucre prévu pour des débits de 4–6 psi, était installé sur une souffleuse qui fonctionnait régulièrement au-delà de 10 psi. Cela a provoqué une défaillance rapide des joints de purge d'air, entraînant des risques de fuite et d'explosion lorsque la poussière de sucre a été atomisée à la base du silo.

La solution : modifier le matériau et la conception du joint de l'écluse, de sorte qu’il puisse subir des pressions de 10 psi et plus pour obtenir de meilleures performances.

Les résultats : notre matériau en Fluorosint™ 207 PTFE résiste mieux à l’usure et aux températures élevées. Utilisé pour le joint du sas, il offre de meilleures performances et une plus grande sécurité de fonctionnement. Le matériau en PTFE est certifié alimentaire et offre d'excellentes performances d'étanchéité afin de réduire les temps d’arrêt et la fréquence des maintenances.

PRODUIT : Fluorosint™ 207 PTFE

SECTEUR : Aliments et liquides

APPLICATION : Joints d'écluse rotative (sas à sucre)

Le défi : dans un microfluidiseur utilisé pour réduire la taille des particules de liquides pharmaceutiques, le fluidiseur et le joint sont exposés à de multiples cycles d’autoclavage pour effectuer la stérilisation. Les différents types de joints utilisés jusque-là subissaient trop de rétreint à la fin de ce cycle intense de vapeur, provoquant rapidement des fuites ou des pannes.

La solution : remplacer la pièce défaillante par un joint en Fluorosint™ 207 PTFE qui présente une meilleure stabilité dimensionnelle et une plus grande résistance que le traditionnel PTFE et autres polyéthylènes.

Les résultats : le Fluorosint™ 207 a d'excellentes propriétés d’étanchéité et de stabilité dimensionnelle. Les joints montés dans la pompe de l'unité de pressurisation fabriqués à partir de ce grade de PTFE ont ainsi pu résister à l'utilisation répétitive requise de 20 minutes par cycle. Le Fluorosint™ 207 offre également une excellente tenue aux flux hyper froids et à l'autoclavage.

PRODUIT : Fluorosint™ 207 PTFE

SECTEUR : Médical et Sciences de la vie

APPLICATION : stérilisation des équipements et instruments

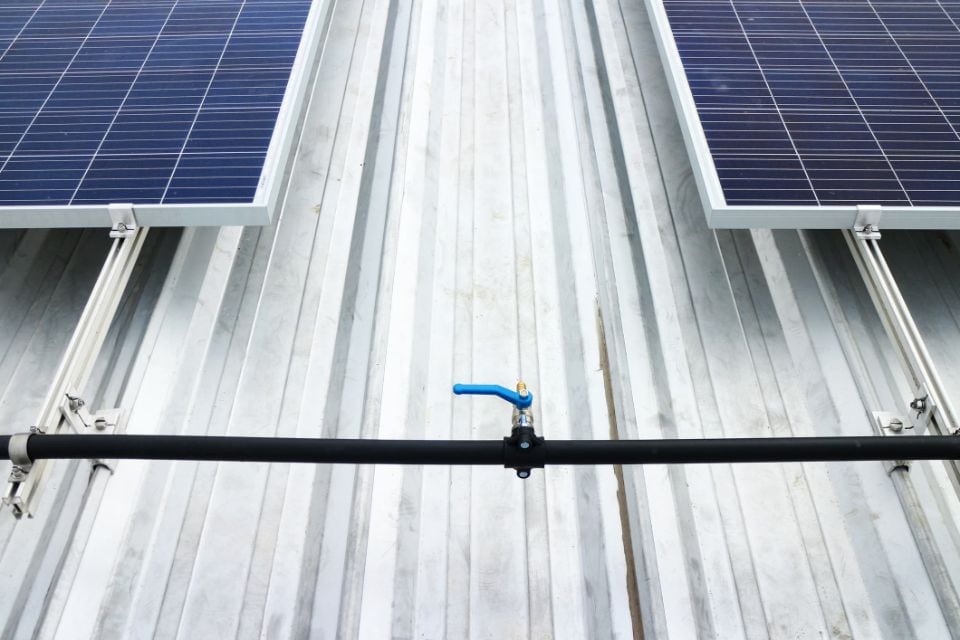

Le défi : Les cellules solaires hautes performances, à faible coût et haut rendement, reposent sur des sièges de vannes qui, dans certains cas, ne remplissaient pas leur rôle ; les pièces étaient coûteuses et devaient être constamment remplacées ; ces pièces n'étaient n'étaient de plus disponibles qu'en Europe et posaient un problème d'approvisionnement pour le fabricant basé aux USA.

La solution : changer la conception de ces sièges en optant pour un matériau en PTFE qui offre une plus grande stabilité à des températures élevées, afin d’obtenir de meilleures performances et de prolonger la durée de vie.

Les résultats : résistant jusqu’à 250°C, les sièges en plastique fabriqués avec notre Fluorosint™ 500 PTFE présentent une meilleure résistance aux produits chimiques et une plus grande stabilité. Ils assurent ainsi un fonctionnement plus fiable sur une durée de vie plus longue. Comme fournisseur mondial et présent aux États-Unis, nous avons permis à ce fabricant américain de réaliser des économies en optant pour le Fluorosint™ 500.

PRODUIT : Fluorosint™ 500 PTFE

SECTEUR : Production d’énergie

APPLICATION : sièges de vannes dans les cellules solaires

Le défi : Les sous-marins pour une ou deux personnes possèdent une écoutille supérieure sphérique en acrylique dont la fermeture du panneau doit pouvoir être assurée, de façon fiable et en toute sécurité, grace à un joint plastique de grande dimension. Le matière utilisée pour le joint doit correspondre aux spécifications de l’ABS (American Bureau of Shipping).

La solution : les dimension capables de nos demi-produits usinables en Nylatron™ MC 907 permettent d'assurer la réalisation de ce joint de grande dimension.

Les résultats : notre joint en Nylatron™ MC 907 PA6 n’a pas besoin d’être lubrifié (éliminant des frais d’installation onéreux), mais offre la résistance à la pression et la stabilité dimensionnelle nécessaires pour que le joint assure une parfaite étanchéité sous l’eau.

PRODUIT : Nylatron™ MC 907 PA6

SECTEUR : Transport

APPLICATION : joint de sphère acrylique de panneau d'écoutille supérieure

Le défi : Les joints des rondelles de butée des équipements de ce secteur doivent être fiables et pouvoir fonctionner pendant de longues périodes dans un environnement agressif.

La solution : fabriquer des rondelles hautes performances avec un polyamide résistant aux impacts, aux températures et à l’usure.

Les résultats : les propriétés autolubrifiantes de notre Nylatron™ NSM PA6 offrent une durée de vie plus longue que tout autre polyamide présent sur le marché. Grâce à sa robustesse et à sa limite pression/vitesse élevée, notre joint résiste à la chaleur du frottement et offre de bonnes performances dans les environnements agressifs et avec des charges extrêmes. Le matériau peut être usiné dans différentes tailles afin de fabriquer des joints de rondelles de butée de toutes dimensions.

PRODUIT : Nylatron™ NSM PA6

SECTEUR : Machinisme lourd

APPLICATION : joints de rondelles de butée pour l’agriculture et la construction

Vous cherchez quelque chose en particulier ? Contactez notre équipe de spécialistes en remplissant le formulaire de contact. Nous sommes prêts à relever votre prochain défi.

Contactez-nous